Completely Czech production

We provide guidance

As the leading Czech manufacturer of swimming pool roofing, we set trends and directions in the industry, which are then adopted by smaller manufacturing companies across the market. Behind all of our production are many years of development and design – we apply our accumulated experience to the design of Sliding Terrace structures. This enables us to guarantee our clients top quality products with a long service life. We guarantee our competitors that we can correct any of their mistakes.

The development centre and production plant are located in Central Bohemia, from where our Sliding Terraces are also exported all over Europe. We are very proud of our professional team, which we are expanding and which is behind this great Czech product from start to finish.

We pride ourselves on quality individualised production, fast and flexible service and products designed exactly according to each customer's needs – exactly in the spirit of our motto: Love your garden.

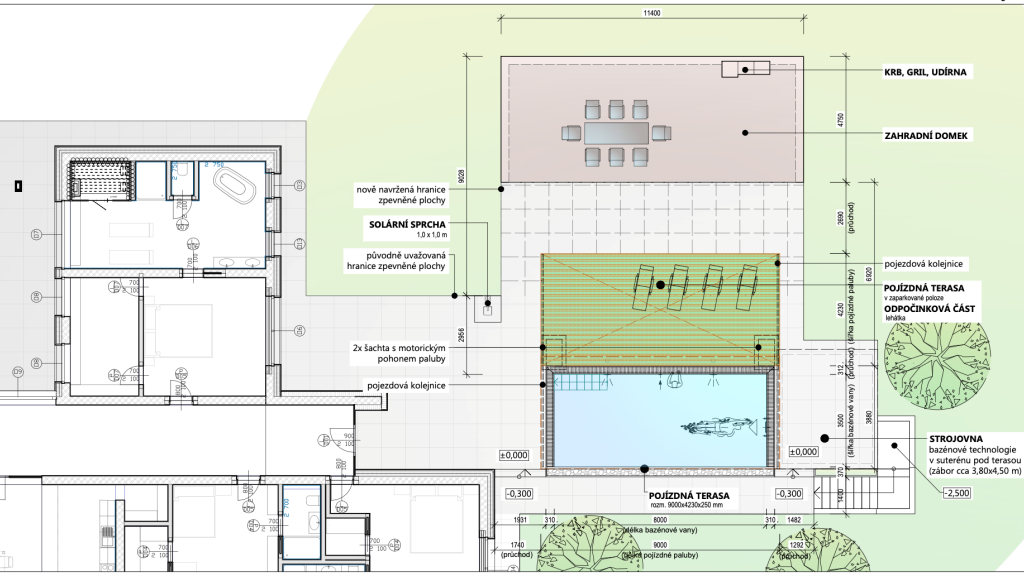

Designing Sliding Terraces

At the beginning of each installation, the local site layout is surveyved with respect to the subsoil around the pool, the snow zone in which the site is located, and the spatial options for offsetting the patio. Once this data has been obtained, an authorised structural calculation for the type of terracce is carried out - for example, a terrace with lateral displacement for an istallation in Prague is dimensioned differently from a longitudinslly sliding terrace in the Krkonoše Mountains. The standard mobile terrace is designed for a load capacity of 100kg/m2 (+safety coefficient of 50kg/m2) and a heavy covering of 30-35 kg/m2. In higher locations, terraces are even rated for a load capacity of 400kg/m2 or more.

Materials used for construction and fasteners

The load-bearing structure is made of top-quality hardened aluminium alloy beams of EN AW-6060 T6 batch which guarantees high load-bearing capacity and low weight. The same is true for the fasteners, where our production exclusively uses A4 grade stainless steel components, i.e., resistant to very aggressive environments such as salt water.

The welding of aluminium profiles is carried out using the TIG method, which places high demands on the skill of the technician. The welds are therefore subjected to strength tests during regular stress tests, which we carry out in our production facility. Everything is subject to the load-bearing capacity and strength of the Sliding Terraces – we are thus able to provide a 10-year warranty on the frame, and a standard 2-year warranty on the moving and mechanically stressed parts.

Construction and Installation of Mobile Terraces

Thanks to its robust construction and high-quality full coverings, the weight of the Sliding Terrace is impressive. It is therefore always necessary to have a solid base for the installation -e.g., foundation strips or a reinforced concrete slab. As part of the purchase of a mobile terrace, we always prepare documentation specifically for the given terrace, according to which the investor prepares their land for the implementation of the terrace cover.

If a new pool is to be built , we recommend that the excavation for the terrace cover already be taken into account.

News & trivia

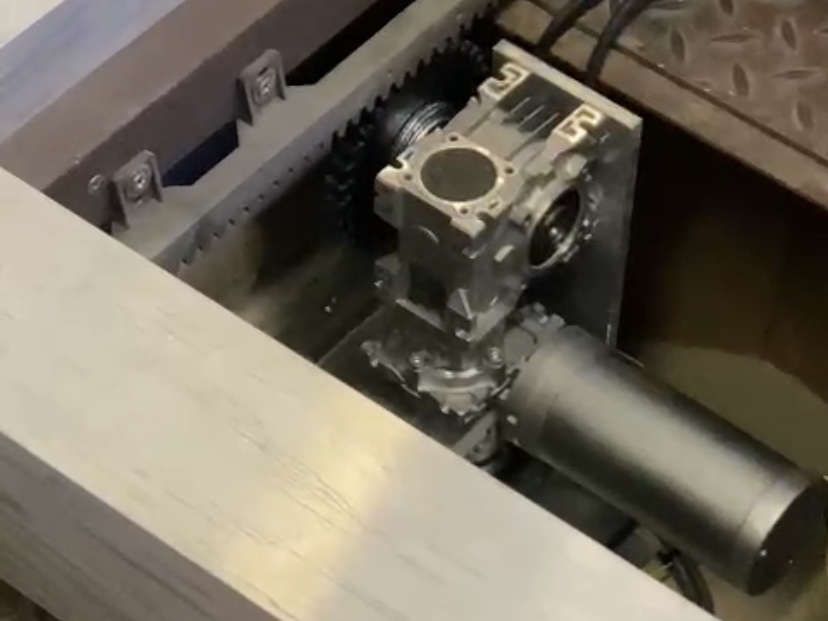

We've developed new motors!

Our clients can soon look forward to a new type of electric motor with an input of only 24V! This revolutionary innovation is now being finalized by our electrical installation specialists and will be launched as soon as it passes homologation. As is traditional in our company – this is a completely Czech product.

Completely noiseless terrace movement? No problem!

We only want the best for our customers – so we try to work only with proven materials with as many components from our production as possible. This is also true for the “motion system“ of our terraces. The rails and castors made from our own silk fibre are thus perfectly and completely noiseless!

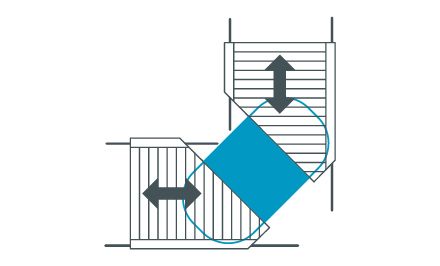

A new type of terrace? The split-folding module is here!

Our terrace coverings not only fulfil safety and design functions, but also excel in their practicality. The latest type of split-folding patio cover, which requires only half the space of standard patios, is the latest proof. The modules automatically fold under themselves and, with a standard load capacity, again save investors' land a little more. Build your dreams with professionals!

A solution for every pool

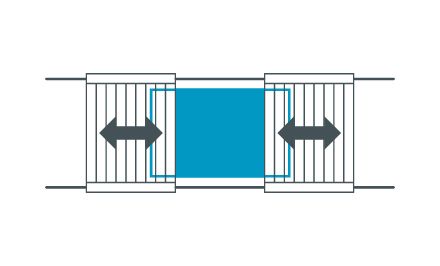

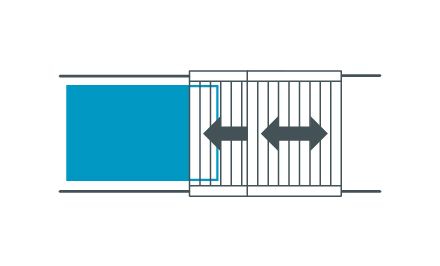

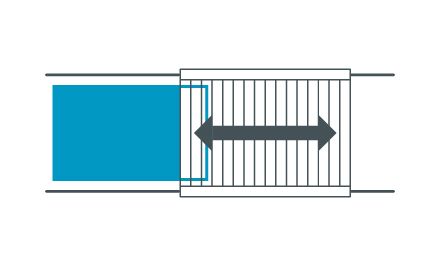

- Longitudinal sliding sliding

- Split sliding sliding

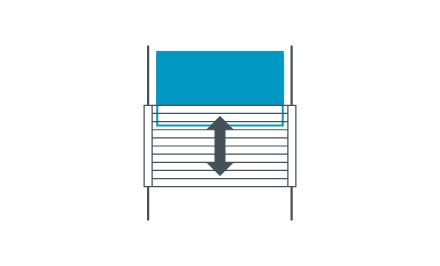

- Folded sliding sliding

- Transwerse sliding sliding

- Atypical shapes sliding

Tailor-made calculations